Template Welding

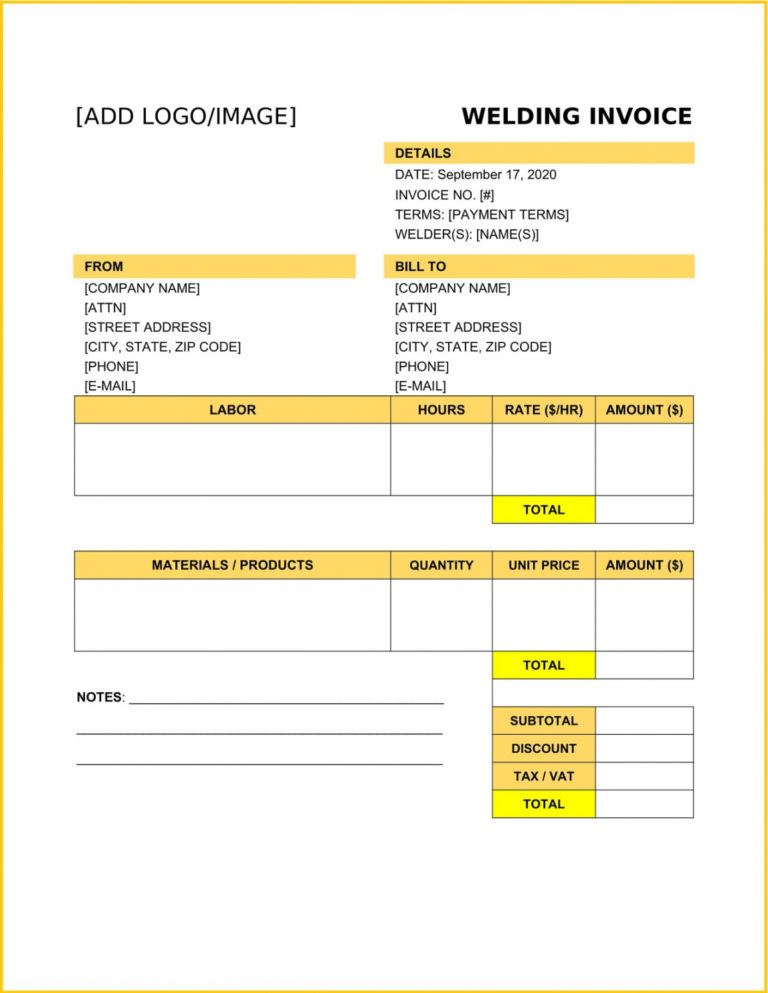

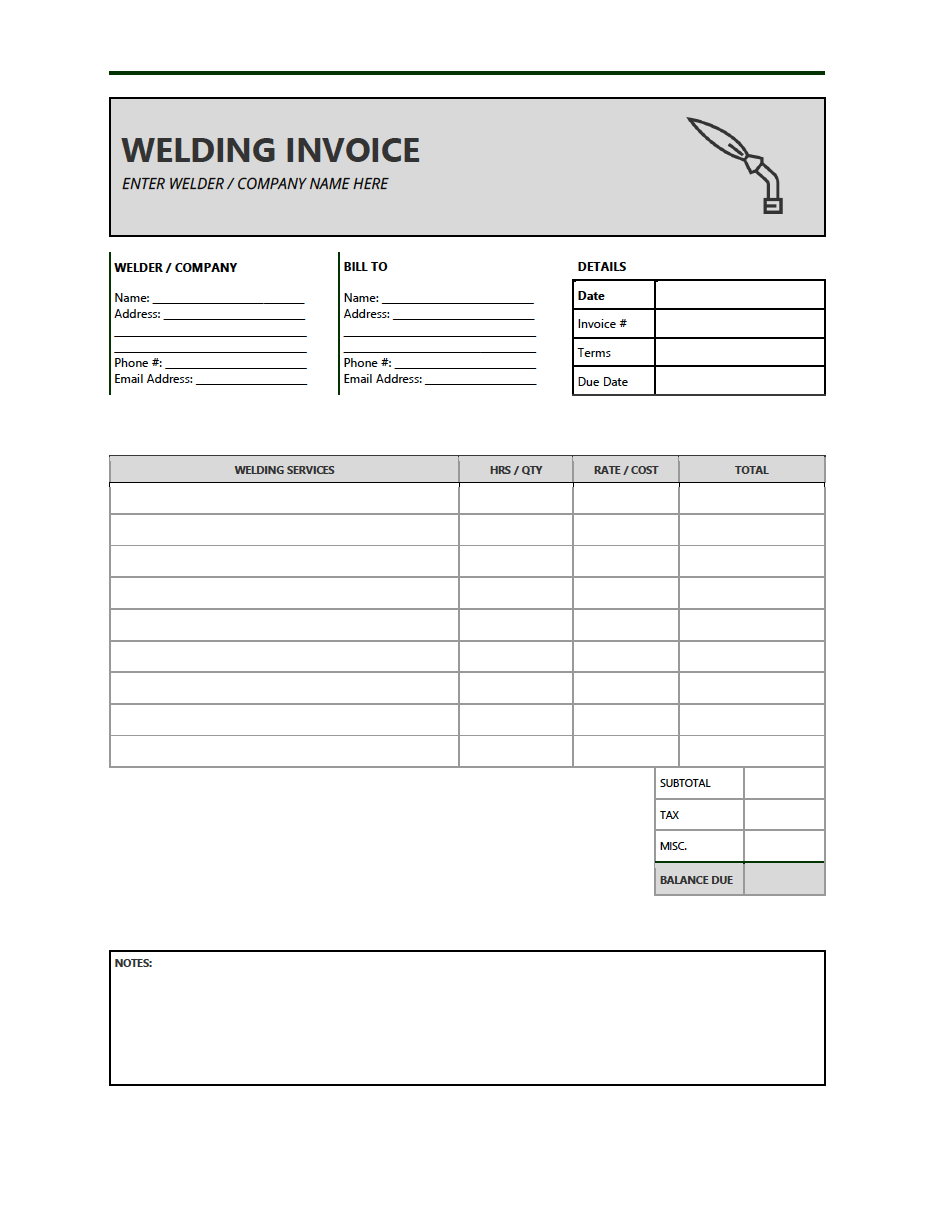

Template Welding - Base metal nonfusing metal cooling rate: Web annex n aws d1.1/d1.1m:2010 354 welding procedure specification (wps) yes prequalified _____ qualified by testing _____ or procedure qualification records (pqr) yes Web welding procedure pass or filler metals current weld type & amps or wire travel layers process class diam polarity feed speed* volts* speed* joint details *** * n/a for manual process. Web size of filler metals: What is the base metal that we’re welding? Joints, base metals, filler metals, positions, preheat, pwht, gas etc. Web this guide has been prepared to assist welding personnel with the preparation of welding procedures required as part of their company certification to csa standards w47.1, w47.2 and w186. Web a welding procedure specification (wps) is a written document providing direction to the welder (or welding operator). With over 5 years of experience in welding and a strong commitment to accuracy and efficiency, i am confident in my ability to contribute to your team. Yes no holding time : It contains all the necessary parameters viz. With over 5 years of experience in welding and a strong commitment to accuracy and efficiency, i am confident in my ability to contribute to your team. Base metal nonfusing metal cooling rate: Web include information such as the welding process, the materials to be welded, the welding parameters, and any special considerations or standards that need to be followed. What is the base metal that we’re welding? Web welding procedure specification examples and templates can be found in annex n of aws d1.1 or annex o of aws d1.5. Asme also offers a wps template. What is the suitable filler metal for the job? This document serves as a guide for the welding process and. Attach photo or video evidence for compliance. Web welding procedure pass or filler metals current weld type & amps or wire travel layers process class diam polarity feed speed* volts* speed* joint details *** * n/a for manual process. Web this guide has been prepared to assist welding personnel with the preparation of welding procedures required as part of their company certification to csa standards w47.1, w47.2 and w186. Joints, base metals, filler metals, positions, preheat, pwht, gas etc. Welders use wpss to produce welds consistently and repeatably, ensuring they meet the required quality standards. Web the key document is the welding procedure specification (wps) which details the welding variables to be used to ensure a welded joint will achieve the specified levels of weld quality and mechanical properties. Dear hiring manager, i am writing to express my interest in the mig welder position at your company. Web 100% fully customisable welding safe work method statement. Web the sample welding procedure specification (wps) form is used to document the details and requirements of a welding procedure. Web a welding wps document, also called a welding procedure specification, describes the welding process, materials, and procedures for producing a weld that meets specified requirements. Web size of filler metals: Web explore our robust welding quality assurance manual template, designed to streamline welding operations, maintain safety, and enhance productivity. What is the base metal that we’re welding? With over 5 years of experience in welding and a strong commitment to accuracy and efficiency, i am confident in my ability to contribute to your team. What is the suitable filler metal. (including ranges, if any) under which the welding process must be performed. Web mig welder cover letter sample. Welders use wpss to produce welds consistently and repeatably, ensuring they meet the required quality standards. Web the sample welding procedure specification (wps) form is used to document the details and requirements of a welding procedure. Web include information such as the. This i discussed in an earlier article on welding procedure. Web a welding wps document, also called a welding procedure specification, describes the welding process, materials, and procedures for producing a weld that meets specified requirements. Web that function is to provide guidance and instructions on how to prepare base metal, setup equipment and produce production welds. What is the. Web this welding procedure specification outlines the parameters for welding, including the welding process, filler material size, current and voltage ranges, travel speed, heat input, gas flow rates, tungsten electrode type, preheat. Web download welding procedure specifications (wps) prepared in accordance with commonly used welding standards, such as asme, aws, iso, and as/nzs. Attach photo or video evidence for compliance.. Web size of filler metals: It provides instructions on how to perform a specific welding process, including information about the materials, equipment, and parameters to be used. Web this welding procedure specification outlines the parameters for welding, including the welding process, filler material size, current and voltage ranges, travel speed, heat input, gas flow rates, tungsten electrode type, preheat. Web. Web size of filler metals: It provides instructions on how to perform a specific welding process, including information about the materials, equipment, and parameters to be used. What is the base metal that we’re welding? Asme also offers a wps template. Web welding procedure pass or filler metals current weld type & amps or wire travel layers process class diam. These settings are not visible to the welder with the hood down Joints, base metals, filler metals, positions, preheat, pwht, gas etc. Web a welding procedure specification (wps) is a written document providing direction to the welder (or welding operator). Web welding procedure pass or filler metals current weld type & amps or wire travel layers process class diam polarity. Joints, base metals, filler metals, positions, preheat, pwht, gas etc. Attach photo or video evidence for compliance. What is the suitable filler metal for the job? Asme also offers a wps template. This document serves as a guide for the welding process and. It provides instructions on how to perform a specific welding process, including information about the materials, equipment, and parameters to be used. What is the suitable filler metal for the job? Welders use wpss to produce welds consistently and repeatably, ensuring they meet the required quality standards. Web explore our robust welding quality assurance manual template, designed to streamline welding. Web download welding procedure specifications (wps) prepared in accordance with commonly used welding standards, such as asme, aws, iso, and as/nzs. This i discussed in an earlier article on welding procedure. Web this welding procedure specification outlines the parameters for welding, including the welding process, filler material size, current and voltage ranges, travel speed, heat input, gas flow rates, tungsten. These settings are not visible to the welder with the hood down Web a welding wps document, also called a welding procedure specification, describes the welding process, materials, and procedures for producing a weld that meets specified requirements. Welders use wpss to produce welds consistently and repeatably, ensuring they meet the required quality standards. It contains all the necessary parameters viz. Web this guide has been prepared to assist welding personnel with the preparation of welding procedures required as part of their company certification to csa standards w47.1, w47.2 and w186. View and sign off welding swms on site via mobile, tablet or laptop. Web explore our robust welding quality assurance manual template, designed to streamline welding operations, maintain safety, and enhance productivity. Web that function is to provide guidance and instructions on how to prepare base metal, setup equipment and produce production welds. Dear hiring manager, i am writing to express my interest in the mig welder position at your company. With over 5 years of experience in welding and a strong commitment to accuracy and efficiency, i am confident in my ability to contribute to your team. Attach photo or video evidence for compliance. Export completed welding swms as pdf or csv in one click. Web include information such as the welding process, the materials to be welded, the welding parameters, and any special considerations or standards that need to be followed. Web this welding procedure specification outlines the parameters for welding, including the welding process, filler material size, current and voltage ranges, travel speed, heat input, gas flow rates, tungsten electrode type, preheat. Yes no holding time : Web welding procedure specification examples and templates can be found in annex n of aws d1.1 or annex o of aws d1.5.Free Welding Invoice Template Example Welding Estimate Template Excel

Welding Templates Free Printable Templates

Visual Weld Inspection template Better than PDF and excel

RapidDesign Welding Template 34R

PowerPoint Template Mining equipment welding done by an engineer (17189)

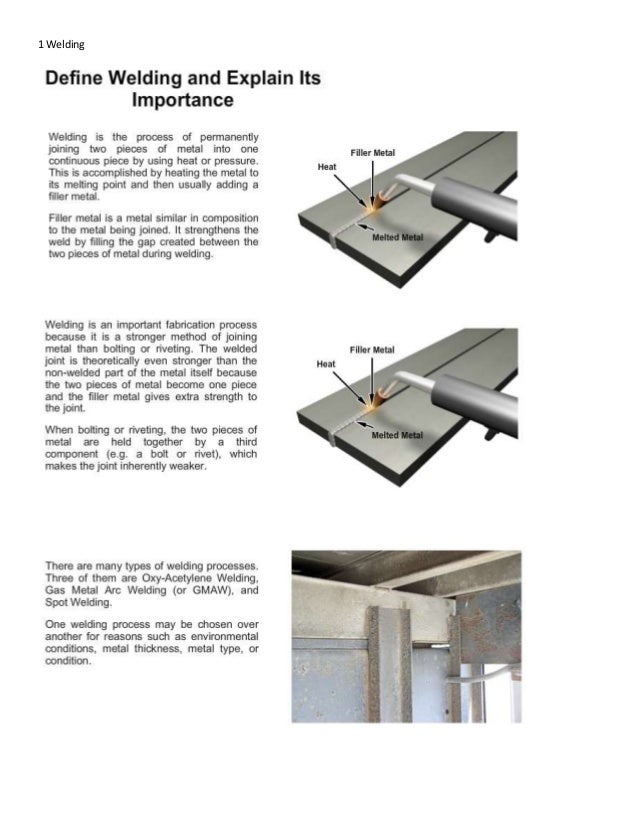

Basic Welding Outline

10 Best Welding Website Templates 2024 Colorlib

10 Best Welding Website Templates 2024 Colorlib

Welding Templates

Free Welding Invoice Template PDF WORD EXCEL

What Is The Base Metal That We’re Welding?

(Including Ranges, If Any) Under Which The Welding Process Must Be Performed.

Web Size Of Filler Metals:

Web The Key Document Is The Welding Procedure Specification (Wps) Which Details The Welding Variables To Be Used To Ensure A Welded Joint Will Achieve The Specified Levels Of Weld Quality And Mechanical Properties.

Related Post: